Reliability = lifeline, which is vital to the success or failure of "electronic products" and "electronic enterprises

Instead of choosing a "low-end factory" to try your luck, it is better to choose a "high-end manufacturer" and make big plans! Ten years of intensive cultivation of "High Reliability Multilayer PCB", "Vongsun" is only to make customers more worry-free, more secure, and more assured .

"High reliability" refers to a longer product life, and there are few or no failures during the product life cycle! With the rapid development of science and technology, all walks of life have put forward higher and higher requirements for product reliability! Product reliability has become an inspection and evaluation index for product quality, and it is also an important weight for companies to enhance their competitiveness and brand image!

1. The importance of PCB high reliability

1) Only highly reliable PCBs can meet the market development needs of customers

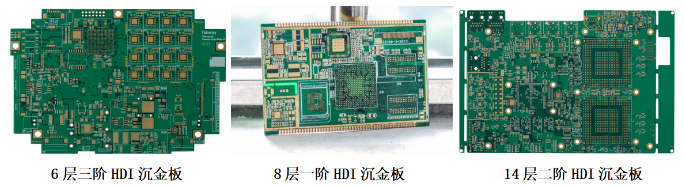

A major feature of the development of modern science and technology is the highly complex structure of the equipment. Its notable sign is the variety of component requirements and the complexity of data. PCB is the core carrier of electronic product link components. The more layers, the more components, and the craftsmanship. The higher the requirements, the greater the impact on reliability, and the higher the requirements for PCB reliability. Only high-reliability PCBs can meet the development needs of our customers.

2) Highly reliable PCB can help customers improve their market competitiveness

Before World War II, Japan's electronic products had a large number of returns due to poor reliability, and they were even almost forced to withdraw from the international market. After World War II, Japan summed up its lessons and continuously improved the reliability level of electronic products, and finally it was able to greatly enhance its market competitiveness and seize a huge share of the international market. With the dual impact of the financial crisis and the new crown epidemic, the current international market competition is particularly fierce. For Huaqiu, only by effectively improving the reliability of PCB can we help customers improve brand reputation and continue to enhance market competitiveness!

3) Highly reliable PCB can help customers obtain higher economic benefits

In 1961, at least 25% of the U.S. Department of Defense's budget was for maintenance. For antenna products sold in the European or North American markets, since the tower operation requires the hiring of qualified professionals, the maintenance cost is slightly different from the single antenna price. In order to improve the reliability of a certain product, Westinghouse in the United States once conducted a comprehensive review and found that improving the reliability level can greatly reduce the maintenance costs of electronic equipment; on the surface, the high-reliability pre-production and control costs will be higher. However, there will be fewer failure rates in the later period, and maintenance costs and downtime losses will be lower. In order to help customers maximize their economic benefits, "Vongsun" is more obsessed with doing PCBs right, doing well, and highly reliable ! !

2. PCB failure and its consequences analysis

As the carrier of electronic components and the hub of circuit signal transmission, PCB has become one of the most important and critical core components in electronic products. Its quality and reliability directly determine the quality and reliability of the entire electronic machine.

With the ever-increasing miniaturization, lightweight, multi-functionalization of electronic products, and the continuous promotion of environmental protection requirements such as lead-free and halogen-free, the PCB industry is moving towards "fine lines, small holes, multiple layers, thin boards, high TG, high frequency , High-speed, high-density, and environmental protection, which has led to the increasing complexity of the internal structure of the PCB, the increase in internal temperature rise, and the deterioration of heat dissipation conditions, which greatly affects the reliability.

Secondly, there are huge differences in the use environment of electronic products, from tropical to frigid zone, from land to deep sea, from high altitude to space, from laboratory to field... In addition to the effects of temperature and humidity, sunlight, dust, and sea water Various environmental conditions, such as salt spray, shock, vibration, cosmic particles, and various radiation, will have varying degrees of impact on the PCB, and even lead to product failure. For example, in a coastal high-salt and high-humidity environment, a thin water film will form on the surface of the object, and when the relative humidity is 65%-80% in the air, the thickness of the water film on the object is 0.001~0.1μm. When the PCB is working with electricity, the water film and the hole copper together form an electrolytic cell, and an electrochemical reaction occurs, and finally black corrosives are generated, which poses a fatal risk to the reliability of the PCB.

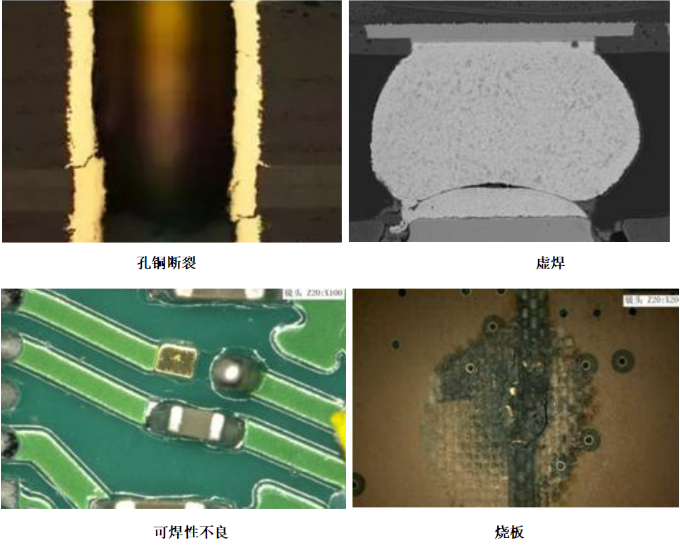

The reasons for PCB failure are various and different, such as the corrosion failure of PTH hole copper, the open circuit failure caused by the bottom crack of the HDI blind hole, the layered plate failure, the ENIG hole ring crack failure, the open and short circuit failure, etc. Different failure types will eventually affect maintenance costs, operating efficiency, economic benefits, brand image, and may even endanger property safety, casualties, and national security!

Everything comes from customer needs, and everything revolves around customer needs. From the early stage of "making a good board with all my heart", now it is highly focused on "high-reliability multilayer board manufacturing".